Sensonic IR-1 is a state-of-the-art gas analyser. It is a class of its own, equipped with up to 6 NDIR sensors, supplemented with up to 3 electrochemical cells. Large, colourful VGA display for data presentation. Compact-flash disk for results (stored in a database form). All administered by PC-104 industrial class computer with Windows CE operating system. Sensonic IR-1 paired with the most efficient gas conditioner creates fully professional gas analysing system that meets the most rigorous requirements and criteria. Recommend for all those who appreciate the most: quality and performance.

Brochure

Features

- Double thermal stabilisation: stabilisation of entire casing and of each NDIR sensor separately - such approach provides the best thermal stabilisation (accuracy to 0.01°C), short warm up time (30 ÷ 60min) and the best accuracy of the NDIR sensors

- Up to 6 NDIR sensors, up to 3 electrochemical cells

- Paired up with professional gas conditioner - Sensonic D-2

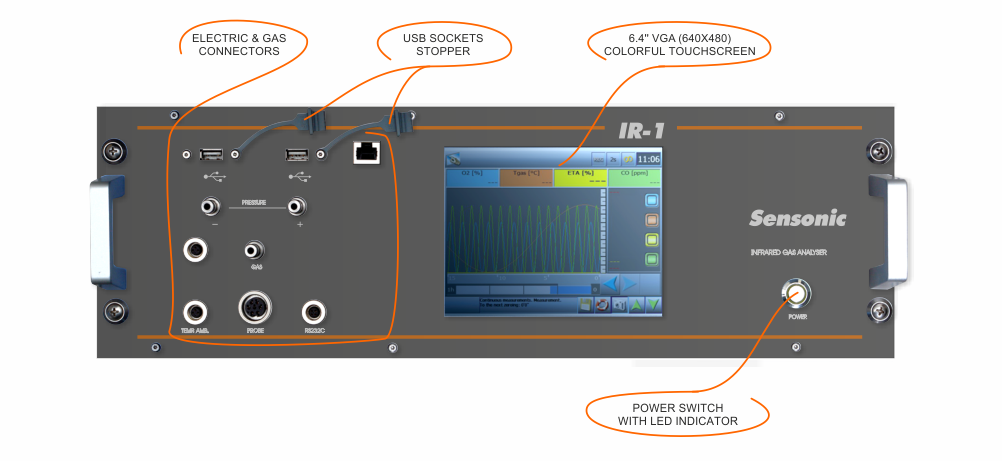

- Large - 6.4", high-resolution - VGA (640x480) colourful display with touch-pad

- PC-104 industrial class computer with Windows CE operating system

- Advanced algorithms to control analyser's work, like warming up, compensation of cross-sensitivity values, response time - all which influence the quality and performance

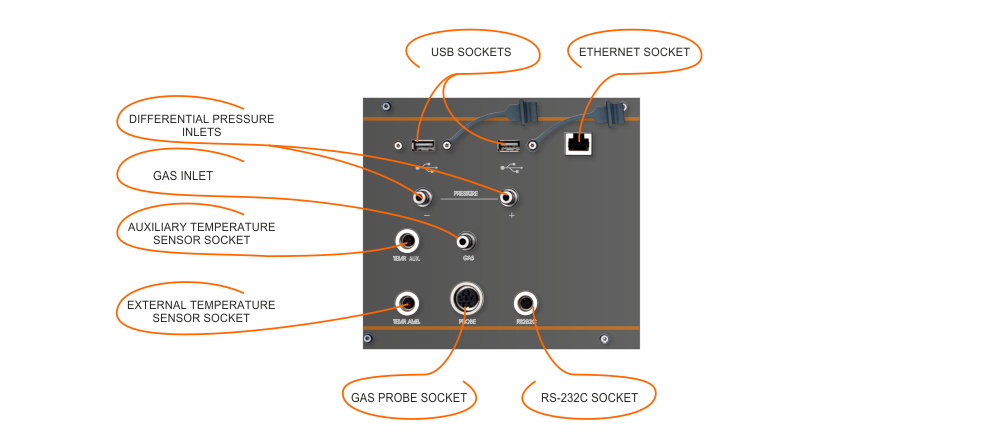

- Measurement of many additional parameters: temperatures (ambient, gas), pressures (atmospheric, differential), flow velocity (with help of Pitot tube), flow control through device and more

- Calculation of all combustion parameters like: stack loss, combustion efficiency,excess air coefficient, dew point temperature, and more

- Communication with PC computer via RS-232C and Ethernet interfaces

- 2x USB port for connecting commercial peripherals (mice, keyboards) and Sensonic IR-1 add-ons (analogue outputs / inputs)

- Optional add-ons: analogue outputs (8-channels), analogue inputs (8-channels) modules

- Optional portable printer

- Results stored in database - possibility to view entire measurement session in graphical form, create measurement reports, export data to csv files, and more

- Database for customers and objects informations

Tech specs

General Parematers

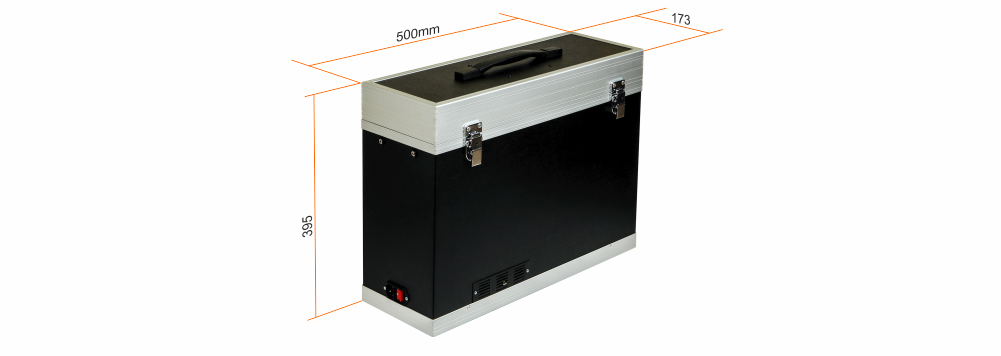

| Dimensions (W x H x D) | 500mm x 395mm x 173mm |

| Weight | 14kg ÷ 18kg |

| Casing's material | Plywood covered with aluminium |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Power supply: input | maximal power consumption | 115 or 230VAC | 150W |

| Operating system | Windows CE 5.0 |

| Display | 6.4” VGA (640x480) |

| Data storage: type | capacity | Compact Flash card | max. 4GB |

| Interface for external devices (USB disk, mouse, keyboard) | 2x USB |

| Communication interface with PC computer | RS-232C, RJ45 (Ethernet) |

| Warming up time | 90min max |

| Warming up temperature | About 18°C above ambient temperature |

| Maximum outside temperature drift that does not affect warming up temperature | ±5°C |

Measurements of gas components

| O2 – (EC) | 20.95% |

| O2 – (EC, PP) | 20.95%, 25%, 100% |

| O2 – (EC, PR) | 25%, 100% |

| CO – (EC) | 20 000ppm, 10% |

| CO – (EC, H2 comp) | 2000ppm |

| CO – (NDIR) | 20 000ppm, 10%, 100% |

| CO2 – (NDIR) | 5%, 10%, 25%, 50%, 100% |

| CxHy – (NDIR) | 5%, 10%, 25%, 50%, 100% |

| NO – (EC) | 5000ppm |

| NO – (NDIR) | 5000ppm |

| NO2 – (EC) | 5000ppm |

| NO2 – (NDIR) | 1000ppm |

| SO2 – (EC) | 5000ppm |

| SO2 – (NDIR) | 5000ppm |

| H2S – (EC) | 1000ppm |

| H2 – (EC) | 2000ppm, 20 000ppm |

| NH3(1) – (EC) | 1000ppm |

| N3O - (NDIR) | 2000ppm |

| CHF3 - (NDIR) | 2.5% |

Notes: (1) – not available with dryer equipped only with Nafion® exchanger as NH3 is destructive for nafion

EC - Electrochemical sensor

PP - Partial pressure

NDIR - Non dispersive infrared sensor

PR - Paramagnetic sensor

PP - Partial pressure

NDIR - Non dispersive infrared sensor

PR - Paramagnetic sensor

Other measurements / calculated results

| Method | Range | |

|---|---|---|

| Tgas – gas temperature | K-type thermocouple | -10 ÷ 1000°C | 0.1°C |

| S-type thermocouple | -10 ÷ 1500°C | 0.1°C | |

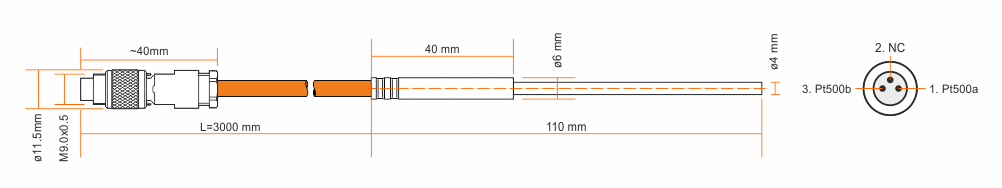

| Tamb – boiler intake air temperature | PT500 resistive sensor | -10 ÷ 100°C | 0.1°C |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa ÷ +25hPa | 1Pa (0.01hPa) |

| Gas flow velocity | Indirect, with Pitot tube & pressure sensor | 1 ÷ 50m/s | 0.1m/s |

| Lambda λ – excess air number | Calculated | 1 ÷ 10 | 0.01 |

| qA – stack loss | Calculated | 0 ÷ 100% | 0.1% |

| Eta η – combustion efficiency | Calculated | 0 ÷ 120% | 0.1% |

| IL – incomplete combustion | Calculated | 0 ÷ 100% | 0.01% |

Drawing

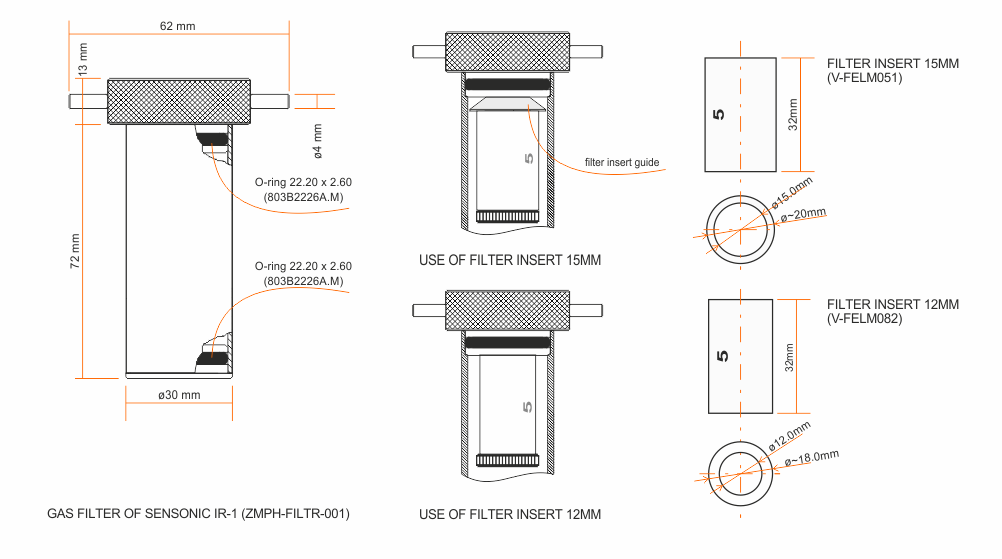

Drawing #1

The filter can be fitted with inserts of different diameters. Insert of 15mm inside diameter is fitted with help of filter insert guide. For 12mm insert, the guide must be removed, and insert is installed directly in the filters's head.

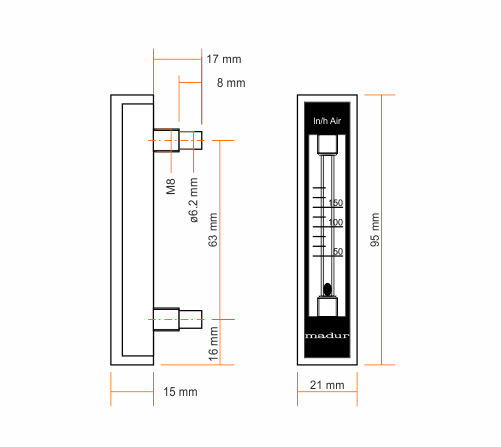

Drawing #2

Flow indicator

Drawing #3

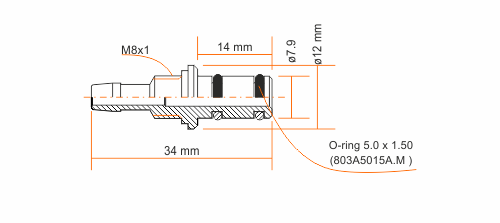

Gas fitting - quick coupler, male part (615A0203A)

Drawing #4

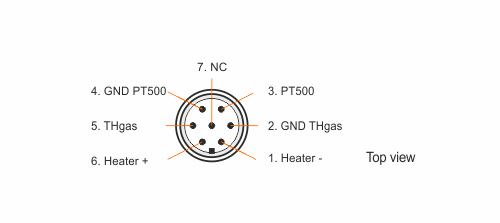

“Probe” connector, Binder 680 series, 7-pin female (512O0710C)

Drawing #5

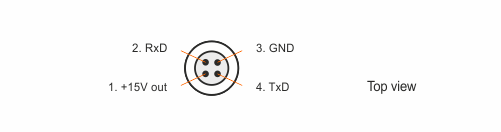

“RS-232C” connector, Binder 712 series, 4-pin female ( 512M0410C)

Drawing #6

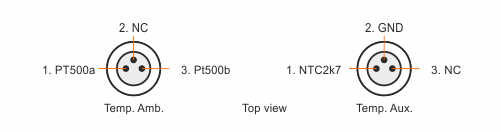

Temperature sensors’ connectors, Binder 712 series, 3-pin female (512M0310C)

Drawing #7

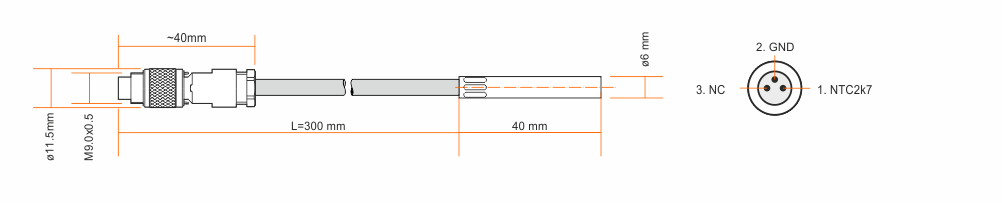

NTC2k7 temperature sensor - connected to Temp. Aux. socket (ZPH2-SENS-NTC)

Drawing #8

PT500 temperature sensor - for boiler inlet air temperature measurements, connected to Temp. Amb. socket (ZCMS-SENS-TEMP)

Drawing #9

Sensonic IR-1 casing dimensions

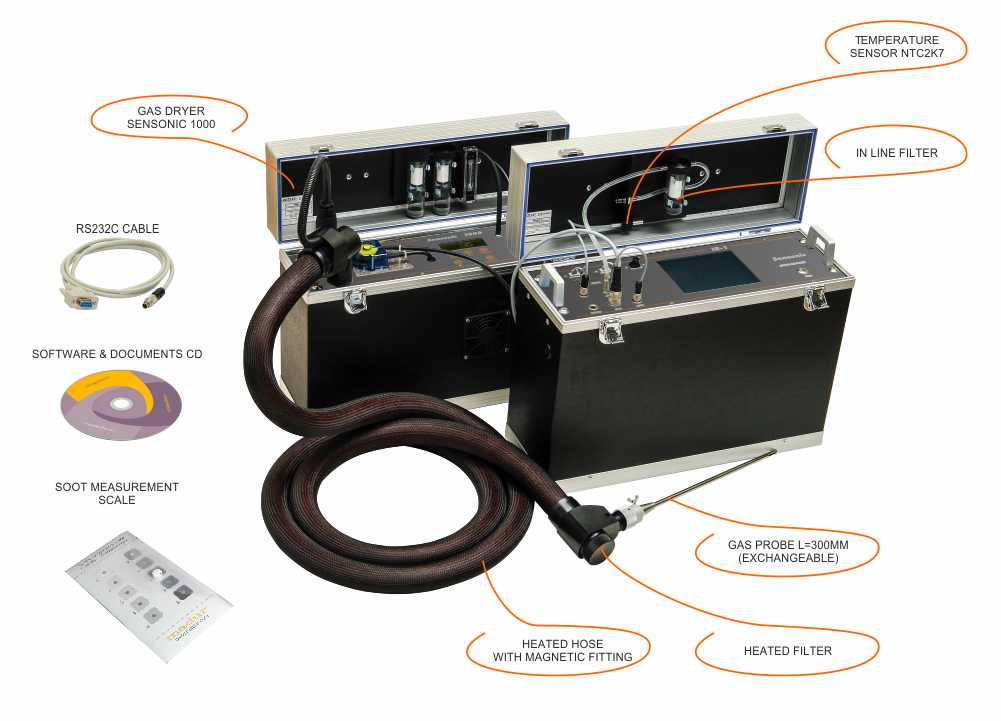

Equipment

Analyser’s standard equipment supplied along with the device

- 3m mains cable (with selectable plug type)

- Single gas filter with condensate trap and filter insert (pore size 5µm)

- Ambient temperature sensor with 300mm cable

- 2.5m RS-232C communication cable with DB9 female connector

- Software CD with programs and manuals

- Quick coupling for the probe holder (3pc)

- Sensonic IR-1 ↔ Sensonic D-2 electric communication cable

- Sensonic IR-1 ↔ Sensonic D-2 gas hose connection

Supplemental equipment - ordered separately, but essential to work with the analyser

Sensonic D-2 Gas conditioner

Heated hose

Gas probe pipe

Boiler’s inlet air temperature sensor

Temperature sensor for thermal stabilisation

Pitot tube

Analogue outputs module

Analogue inputs module

Martel portable printer with USB cable

Sensonic IR-1 ↔ Sensonic D-2 electric communication cable

Sensonic IR-1 ↔ Sensonic D-2 gas tube