The largest of madur’s analysers equipped with electrochemical cells.

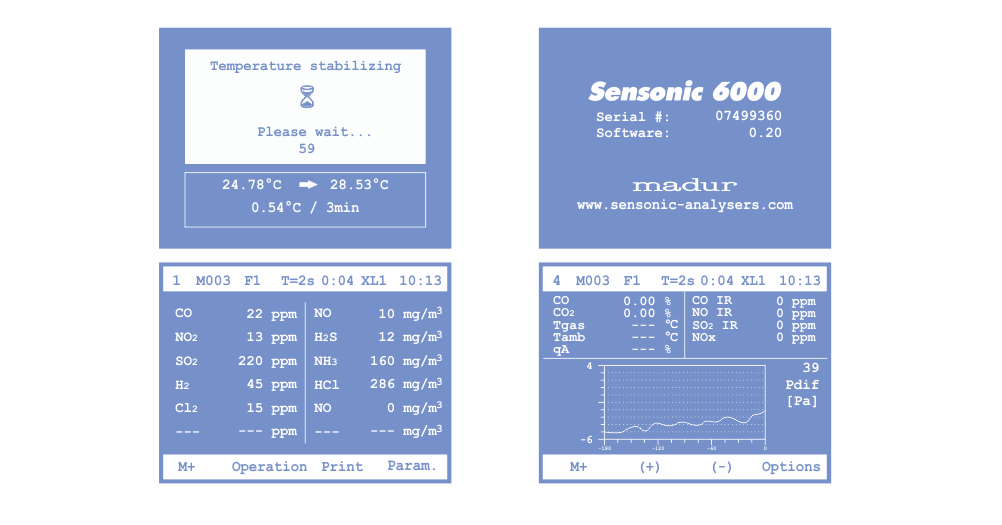

It can fit even up to 7 EC cells and up to 3 NDIR sensors. Sensonic 6000 has a large (320x240), graphical LCD with backlighting.

Datalogger with SD card for storing results and built-in ribbon printer for standard (non-thermal) paper.

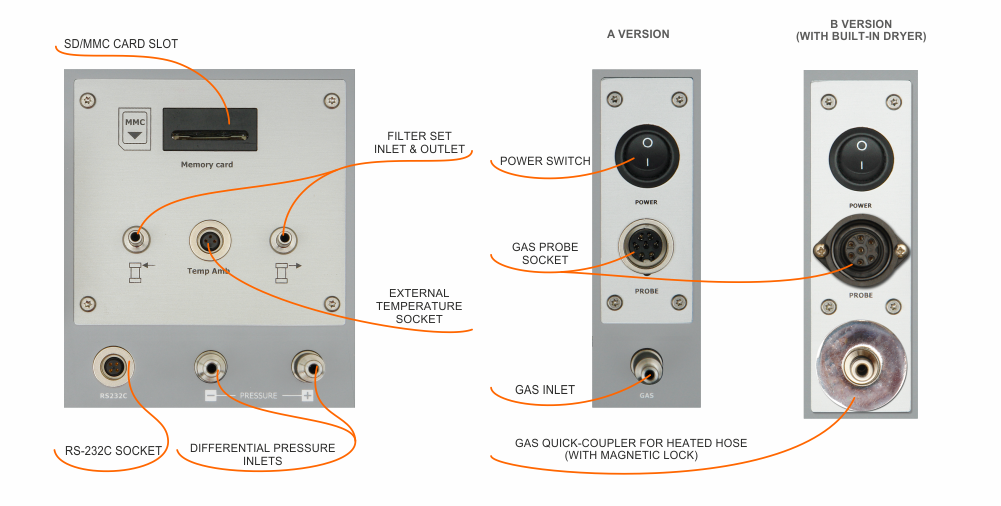

Analyser is offered in two versions:

Analyser is offered in two versions:

- In basic configuration analyser is not equipped with the gas dryer and works with the probe holder + gas probe pipe. It can be paired with Sensonic D-2 gas dryer with heated hose.

- Analyser equipped with a built-in NAFION® type gas dryer and heated hose - configuration especially recommended for measurement of gases highly reactive with water or disturbed by its presence (SO2, HCl, NO2, Cl2)

Features

- Equipped with up to 7 electrochemical cells

- Equipped with up to 3 NDIR sensors

- Built-in 58mm ribbon, graphic printer

- Measurements of gas and ambient temperatures, optionally 8 additional inputs for temperature sensors

- Built-in rechargeable battery for up to 8 hours of operating (for basic configuration with probe holder + probe pipe)

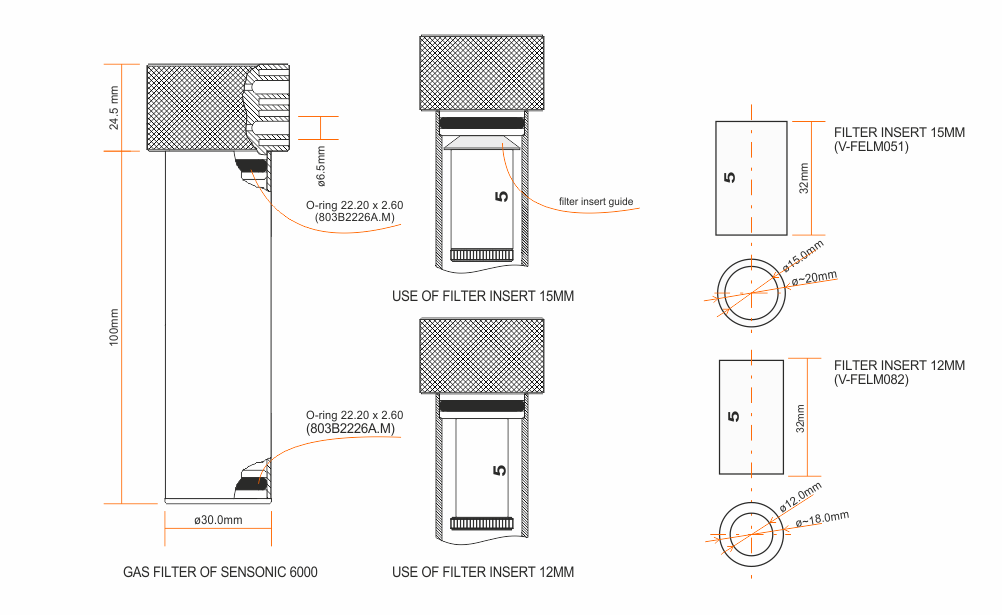

- Additional gas filter with condensate trap (installed in the lid)

- Differential pressure sensor - for measurements of chimney draft and flow velocity (with help of Pitot tube)

- Soot measurement program

- Analogue outputs (4-20mA / 0-10V) - optional

- SD card data-logger for saving results

- Calculations of many additional parameters

- Firmware for gas calibrations

For analyser in A version:

- Works with madur standard probe holder and probe pipe

- Possibility to work with full-size gas dryers (like Sensonic D-2)

For analyser in A version:

- Built-in NAFION® dryer with peristaltic pump for condensation removal

- Driver for heated hose

- Works with heated hose with built-in heated gas filter and with standard M30x1 fitting, that fits all madur gas probes with K-type thermocouples

Tech specs

General parameters - Version A (without built-in dryer)

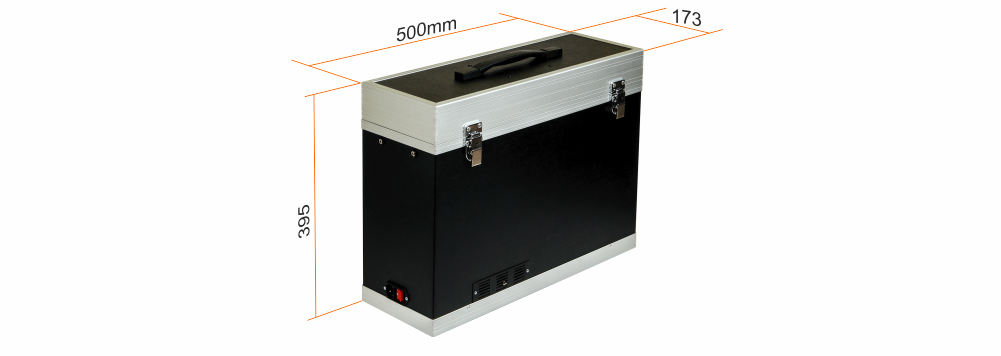

| Dimensions (W x H x D) | 500 x 395 x 173mm |

| Weight | 12.2 ÷ 13.2 kg |

| Casing's material | Plywood covered with aluminium |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Power supply: Input | maximal power consumption | 115VAC or 230VAC | 90W (without heated hose) |

| Battery: type | work time | charging time | Lead-acid, rechargeable 3x6V / 4.5Ah | 16h | 12h |

| Data memory: type | size | number of results | SD flash card | max 4GB | practically unlimited |

| Display | Graphical LCD 320 x 240, with variable contrast and back-light |

| Printer | High-speed dot matrix, graphic printer for 2.25” (57.5 ± 0.5mm) normal paper |

| Gas pump | gas flow | Diaphragm, max 2l/min (with automatic flow control) | 90l/h (1.5l/min) |

| Purging pump for CO sensor | Diaphragm, max 1.5l/min |

| Communication interface with PC computer | RS-232C |

| Gas filtering | Built-in final filter with replaceable insert |

General parameters - Version B (with built-in Nafion® dryer)

| Dimensions (W x H x D) | 500 x 395 x 173mm |

| Weight | 13.7 ÷ 14.7 kg |

| Casing's material | Plywood covered with aluminium |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Power supply: Input | maximal power consumption | 115VAC or 230VAC | 90W (without heated hose) |

| Battery: type | work time | charging time | Lead-acid, rechargeable 3x6V / 4.5Ah | 16h | 12h |

| Data memory: type | size | number of results | SD flash card | max 4GB | practically unlimited |

| Display | Graphical LCD 320 x 240, with variable contrast and back-light |

| Printer | High-speed dot matrix, graphic printer for 2.25” (57.5 ± 0.5mm) normal paper |

| Gas pump | gas flow | Diaphragm, max 2l/min (with automatic flow control) | 90l/h (1.5l/min) |

| Purging pump for CO sensor | Diaphragm, max 1.5l/min |

| Communication interface with PC computer | RS-232C |

| Gas filtering |

|

Built-in gas dryer, heated hose driver, heated hose

Concerns only the B version (with built-in Nafion® dryer)

| Dryer type | Based on Nafion® exchanger |

| Drying method | Water transfer through Nafion® membrane driven by partial vapour pressure differential – first order kinetic reaction |

| Maximum gas flow for efficient drying | 100 l/h |

| Heated hose temperature | +120°C electronically stabilised |

| Heated hose temperature hysteresis | ~ 5°C |

| Heated hose length | 3m (optionally 5m or 10m) |

| Heated hose power consumption | 360W (max) |

| Heated hose thermocouple wires | K-type (S-type optionally) |

Measurements of gas components

| O2 – (EC, PP) | 20.95%, 25%, 100% |

| CO – (EC) | 20 000ppm, 10% |

| CO – (EC, H2 comp) | 2000ppm |

| CO – (NDIR) | 10%, 100% |

| CO2 – (NDIR) | 25%, 50%, 100% |

| CxHy – (NDIR) | 5%, 25%, 100% |

| NO – (EC) | 5000ppm |

| NO2 – (EC) | 1000ppm |

| SO2 – (EC) | 5000ppm |

| H2S – (EC) | 1000ppm |

| H2 – (EC) | 2000ppm, 20 000ppm |

| NH3 – (EC) | 1000ppm |

| CL2 – (EC) | 250ppm |

| HCl – (EC) | 50ppm |

| CL2 - (EC) | 250ppm |

| HCl - (EC) | 50ppm |

EC - Electrochemical sensor

PP – partial pressure

NDIR – non dispersive Infrared sensor

PP – partial pressure

NDIR – non dispersive Infrared sensor

Other measurements / calculated results

| Method | Range | |

|---|---|---|

| Tgas - gas temperature | K-type thermocouple | 10 ÷ 1000°C | 0.1°C |

| S-type thermocouple | -10 ÷ 1500°C | 0.1°C | |

| Tamb - boiler intake air temperature | PT500 resistive sensor | -10 ÷ 100°C | 0.1°C |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa ÷ +25hPa | 1Pa (0.01hPa) |

| Gas flow velocity | Indirect, with Pitot tube & pressure sensor | 1 ÷ 50m/s | 0.1m/s |

| Lambda λ – excess air number | Calculated | 1 ÷ 10 | 0.01 |

| qA – stack loss | Calculated | 0 ÷ 100% | 0.1% |

| Eta η – combustion efficiency | Calculated | 0 ÷ 120% | 0.1% |

Drawing

Drawing #1

Drawing #2

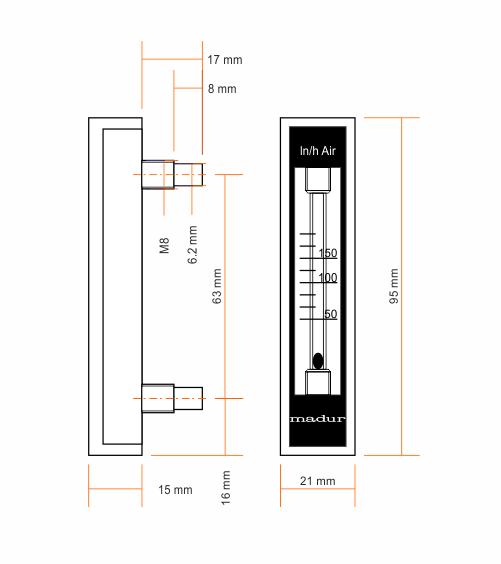

Sensonic 6000 Flow indicatior (610A0001B)

Drawing #3

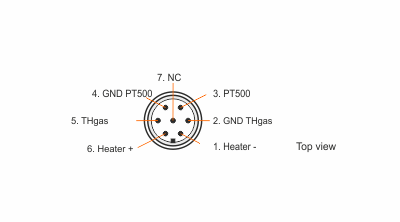

“Probe” connector in the A version, Binder 680 series, 7-pin female (512O0710C)

Drawing #4

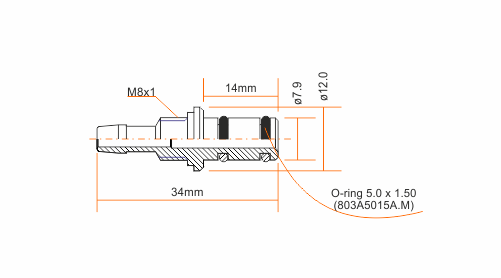

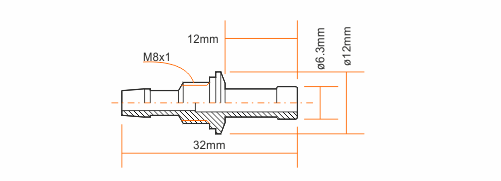

Gas fitting in the A version - quick coupler, male part (615A0203A)

Drawing #5

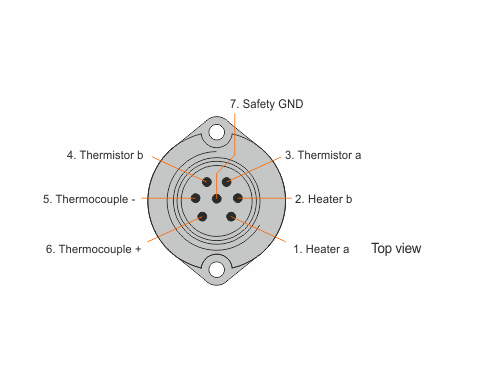

“Probe” connector in the B version, Binder 693 series, 7-pin female (512O0710A)

Drawing #6

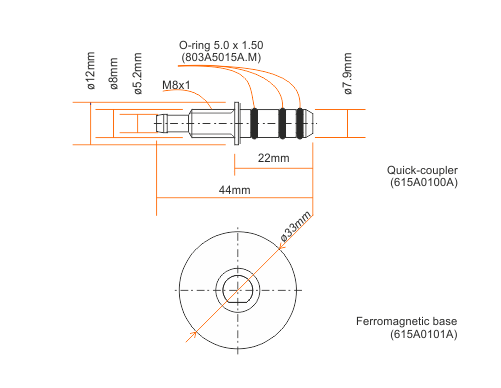

Heated hose magnetic fitting in the B version (male part)

Drawing #7

Fitting for filter hoses (615A0003C)

Drawing #8

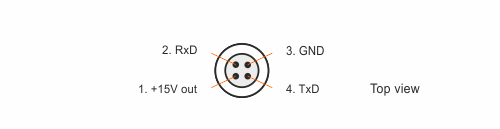

“RS-232C” connector, Binder 712 series, 4-pin female (512M0410C)

Drawing #9

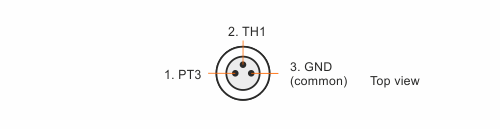

“Temp Amb” connector, Binder 712 series, 3-pin female (512M0310C)

Drawing #10

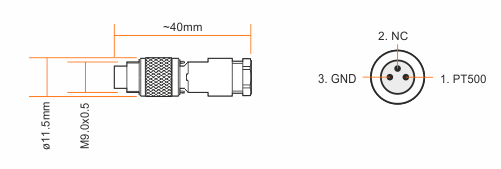

PT500 temperature sensor connected toTemp. Aux. socket (513M0300C)

Drawing #11

Equipment

Analyser’s standard equipment supplied along with the device

- 3m mains cable (with selectable plug type)

- Comparison scale with paper filters for the soot test

- Gas filter with condensation trap and replaceable filter insert (pore size 5µm)

- Flow indicator

- Data-logger with 2GB SD card

- 2.5m RS-232C communication cable with DB9 female connector

- Software CD with programs and manuals

- Quick-couplers for the pressure sensor (2pc.)

- External ambient temperature sensor (1pc.)

Supplemental equipment - ordered separately, but essential to work with the analyser

Probe holder

Heated hose

Gas probe pipe

Optional equipment

Ambient temperature sensor

Pitot tube

RS-232C to USB converter

Bluetooth communication module