Professional flue gas analyser that combines high quality of sample conditioning with great measurement

accuracy contained in a compact soft casing. Analyser is equipped with heated hose with heated filter,

built-in high efficient condensation dryer.

It can be fitted with up to 9 sensors (electrochemical cells and NDIR sensors).

Has built-in pressure sensor, large internal memory for results and built-in ribbon printer for standard (non-thermal) paper.

Brochure

Brochure

Features

- Equipped with up to 7 electrochemical cells

- Equipped with up to 2 NDIR sensors

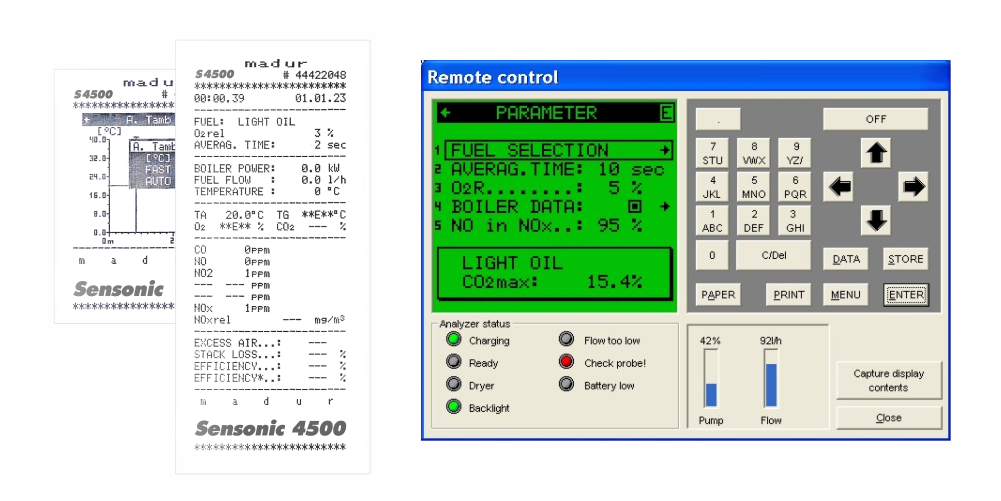

- Built-in 58mm ribbon, graphic printer

- Built-in rechargeable battery for up to 8 hours of operation

- Built-in Peltier dryer with peristaltic pump for condensate removal

- Equipped with heated hose with built-in heated gas filter

- Heated hose with standard M30x1 fitting, fits all madur gas probes with K-type thermocouples

- Additional gas filter with condensate trap

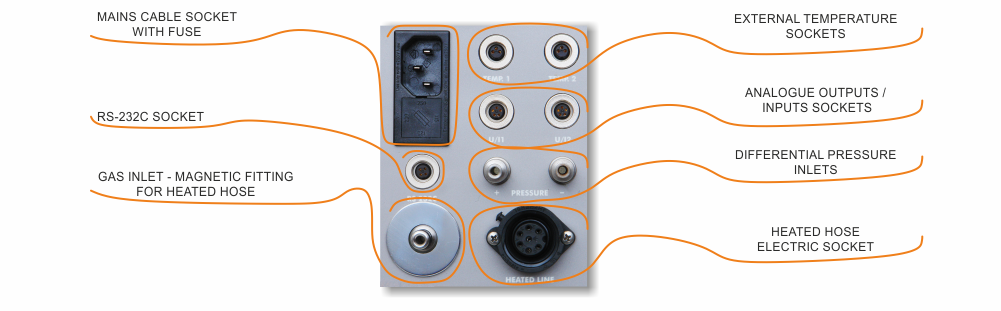

- Differential pressure sensor - for measurements of chimney draft and flow velocity (with help of Pitot tube)

- Soot measurement program

- Measurements of gas and ambient temperatures, optionally 2 additional inputs for temperature sensors

- Analogue outputs (4-20mA / 0-10V) - optional

- Built-in large memory for results, two formats of data savings

- Calculations of many additional parameters

- Firmware for gas calibrations

Tech specs

General Parematers

| Dimensions (W x H x D) | 470 x 310 x 160mm |

| Weight | 12.0÷12.8kg |

| Casing material | Aluminium padded with foam and fabric (polyester) |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | 0°C ÷ +55°C |

| Power supply: Input | maximal power consumption | 115VAC or 230VAC | 90W (without heated hose) |

| Battery: type | work time | charging time | Lead-acid, rechargeable 12V / 2.2Ah | 7h | 14h |

| Data memory: size | number of results | 32kB | 30 reports + 10 banks (1024 sets of data) |

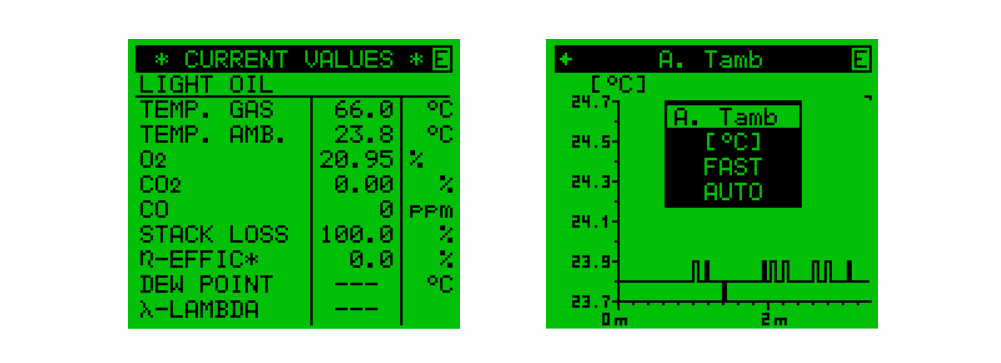

| Display | Graphical LCD 128 x 128, with variable contrast and backlighting |

| Printer | High-speed dot matrix, graphic printer for 57mm normal paper |

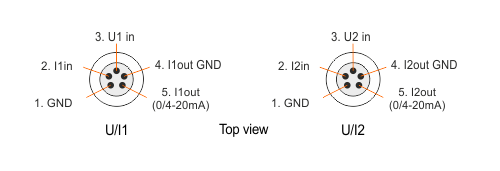

| Analogue outputs (optional) | Two current (0/4÷20mA) or voltage (0÷10V) outputs |

| Gas pump | gas flow | Diaphragm, max 2l/min (with automatic flow control) | 90l/h (1.5l/min) |

| Purging pump for CO sensor | Diaphragm, max 1.5l/min |

| Communication interface with PC computer | RS-232C |

| Gas filtering |

|

Built-in gas dryer, heated hose driver, heated hose

| Drying method | Water condensation by rapid cooling down |

| Cooler type | Based on Peltier element |

| Cooler temperature | +5°C electronically stabilised |

| Cooler temperature hysteresis | ~ 1°C |

| Maximum gas flow for efficient drying | 100l/h |

| Condensate pump | Peristaltic, 38ml/min. |

| Heated hose temperature | +120°C electronically stabilised |

| Heated hose temperature hysteresis | ~ 5°C |

| Heated hose length | 3m (optionally 5m or 10m) |

| Heated hose power consumption | 360W (max) |

| Heated hose thermocouple wires | K-type (S-type optionally) |

Measurements of gas components

| O2 – (EC) | 20.95% |

| O2 – (EC, PP) | 20.95%, 25%, 100% |

| CO – (EC) | 20 000ppm, 10% |

| CO – (EC, H2 comp) | 2000ppm |

| CO – (NDIR) | 10%, 100% |

| CO2 – (NDIR) | 25%, 50%, 100% |

| CxHy – (NDIR) | 5%, 25%, 100% |

| NO – (EC) | 5000ppm |

| NO2 – (EC) | 1000ppm |

| SO2 – (EC) | 5000ppm |

| H2S – (EC) | 1000ppm |

| H2 – (EC) | 2000ppm, 20 000ppm |

| NH3 – (EC) | 1000ppm |

| CL2 - (EC) | 250ppm |

| HCl - (EC) | 50ppm |

EC - Electrochemical sensor

PP - Partial pressure

NDIR - Non dispersive infrared sensor

PP - Partial pressure

NDIR - Non dispersive infrared sensor

Other measurements / calculated results

| Method | Range | |

|---|---|---|

| Tgas – gas temperature | K-type thermocouple | -10 ÷ 1000°C | 0.1°C |

| S-type thermocouple | -10 ÷ 1500°C | 0.1°C | |

| Tamb – gas temperature | PT500 resistive sensor | -10 ÷ 100°C | 0.1°C |

| PT500 resistive sensor | ||

| T1 & T3 – external temperature | K-type thermocouple | -10 ÷ 1000°C | 0.1°C |

| S-type thermocouple | -10 ÷ 1500°C | 0.1°C | |

| T2 & T4 – external temperature | PT500 resistive sensor | -10 ÷ 100°C | 0.1°C |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa ÷ +25hPa | 10Pa (0.01hPa) |

| Gas flow velocity | Indirect, with Pitot tube & pressure sensor | 1 ÷ 50m/s | 0.1m/s |

| Lambda λ – excess air number | Calculated | 1 ÷ 10 | 0.01 |

| qA – stack loss | Calculated | 0 ÷ 100% | 0.1% |

| Eta η – combustion efficiency | Calculated | 0 ÷ 120% | 0.1% |

| U1÷U2 – external analogue input (voltage) | Delta-sigma ADC | -20V ÷ +20V | 0.01V |

| I1÷I2 – external analogue input (current) | Delta-sigma ADC | -20mA ÷ +20mA | 0.01mA |

Drawing

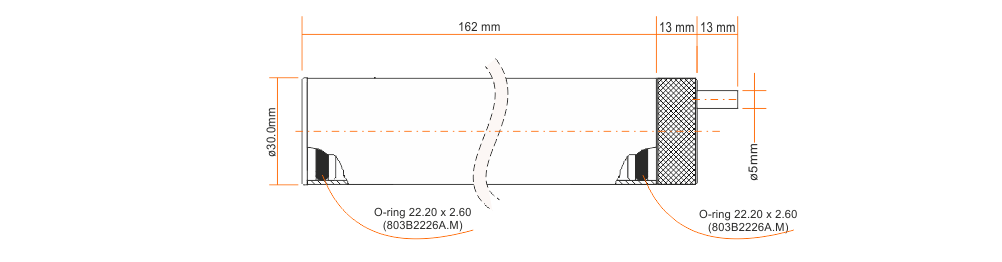

Drawing #1

Sensonic 4500 filter can be fitted with inserts of different diameters: Insert of 15mm inside diameter is fitted with help of filter insert guide. For 12mm insert, the guide must be removed, and insert is installed directly in the filters's head.

Drawing #2

Condensate container of Sensonic 4500 gas analyser

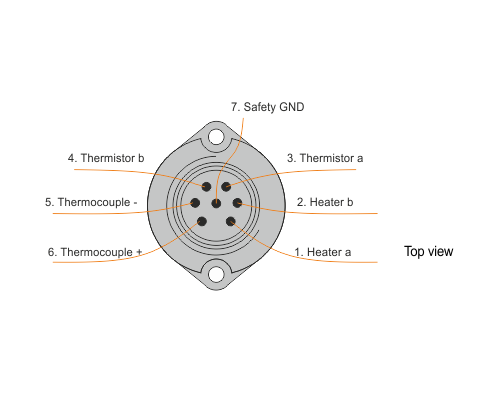

Drawing #3

“Probe” connector, Binder 693 series, 7-pin female (512O0710A)

Drawing #4

Heated hose magnetic fitting (male part)

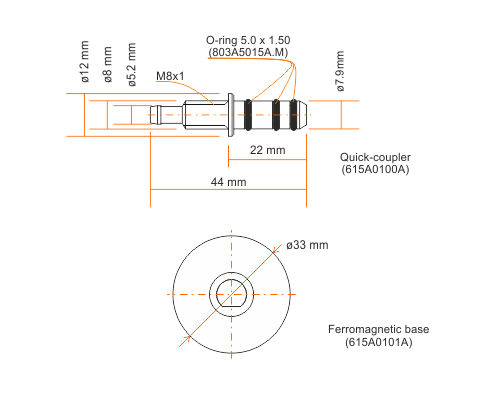

Drawing #5

Pressure sensor fitting - quick coupler, male part (615A0203A)

Drawing #6

“Temp1” & “2” connectors, Binder 712 series, 3-pin female (512M0310C)

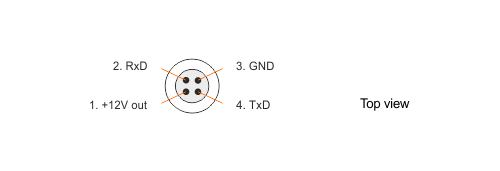

Drawing #7

“RS-232C” connector, Binder 712 series, 4-pin female (512M0410C)

Drawing #8

“U/I1” & “U/I2” connectors, Binder 712 series, 5-pin female (512M0510C)

Drawing #9

Analyser’s dimensions

Equipment

Analyser’s standard equipment supplied along with the device

- 3m mains cable (type of plug to be selected)

- Heated hose of selected length and supply voltage with heated filter and carrying bag

- Single gas filter with condensation trap and filter insert (pore size 5µm)

- Condensation container

- 2.5m RS-232C communication cable with DB9 female connector

- Software CD with programs and manuals

- Quick coupler for the pressure sensor fittings (2pc.)

Supplemental equipment - ordered separately, but essential to work with the analyser

Heated hose

Gas probe pipe

Optional equipment

Ambient temperature sensor

Pitot tube

Soot test adapter

RS-232C to USB converter

Bluetooth communication module