Sensonic 1400 hand-held analyser that can be equipped with up to 4 EC cells.

Thanks to the size of its housing it is equipped with Li-ion battery by default.

Manufactured according to the principles of EN50379.

Brochure

Brochure

Features

- Equipped with 3 or 4 electrochemical cells (typical configuration: O2, CO, NO/NOx, SO2)

- Works with an external portable printer via wireless communication (IR LED)

- Built-in rechargeable Li-ion battery for up to 10 hours of operation

- Probe holder with a standard M30x1 fitting, fits all madur gas probes with the K-type or S-type thermocouples

- Availbility of soot measurements (with proper probe holder)

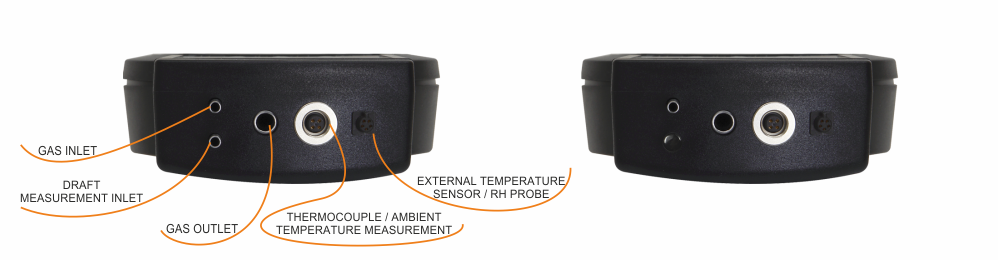

- Built-in pressure sensor for chimney draft measurements and continuous pump flow control

- Optional second pressure sensor (differential) – for measurements of chimney draft and flow velocity (with help of Pitot tube)

- Cooperation with digital %RH and temperature probe

- Measurements of gas and ambient temperatures

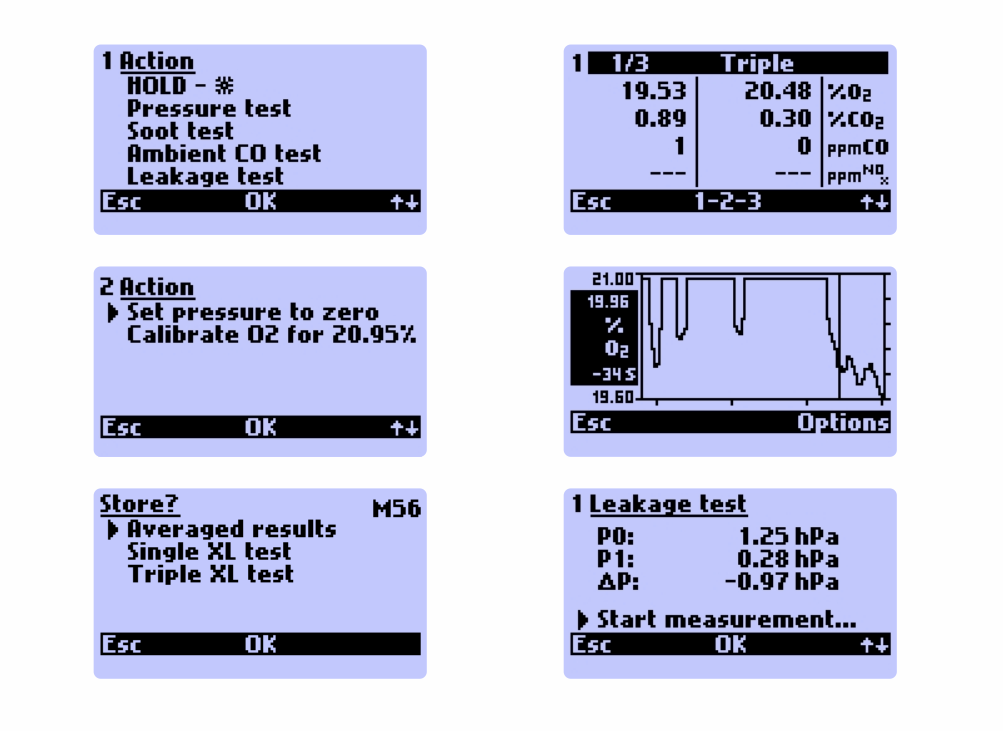

- Results presented on LCD display (128x64) with back-lighting

- Built-in large memory for results savings

- Calculations of many additional parameters

- Firmware for gas calibration

Two versions of analyser are available:

- Standard version with single pressure sensor

- Version with additional differential pressure sensor (that allows to perform measurements of gas flow velocity)

Tech specs

General parameters - Version A (with single pressure sensor)

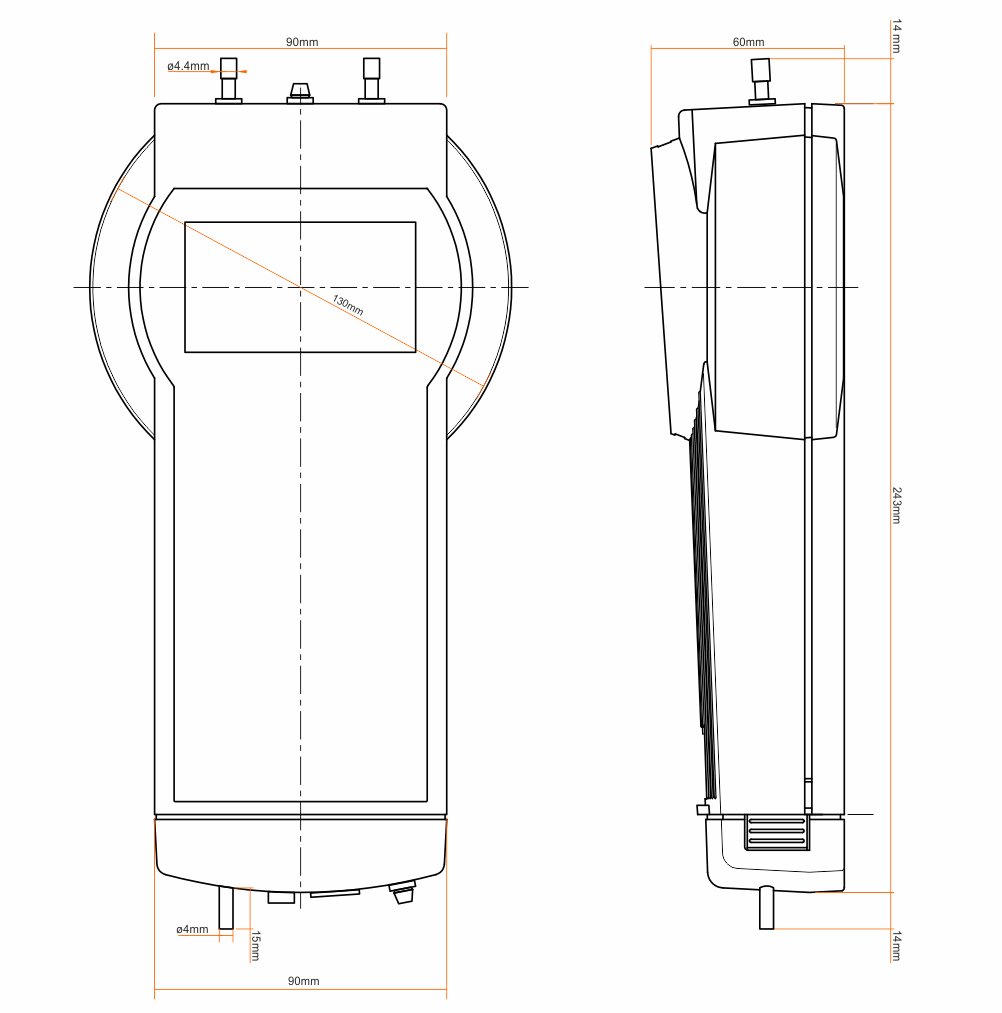

| Dimensions (W x H x D) | 243 x 130 x 60mm 257 x 130 x 60mm (with gas connectors) |

| Weight | 615g |

| Housing material | ABS case, rubber protective boot (optional) |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Power supply | Built-in Li-ion rechargeable battery (1600mAh) |

| Operating time (fully charged battery) | Up to 16 hours |

| Number of gas sensors | 3 or 4 |

| Memory for results | For 64 measurement reports |

| Display | Graphical LCD 128x64, with variable contrast and LED backlight |

| Gas pump | Diaphragm, max 0.6 ÷ 0.9l/min. |

| Printer | External thermal IR printer MCP 8850 with charger |

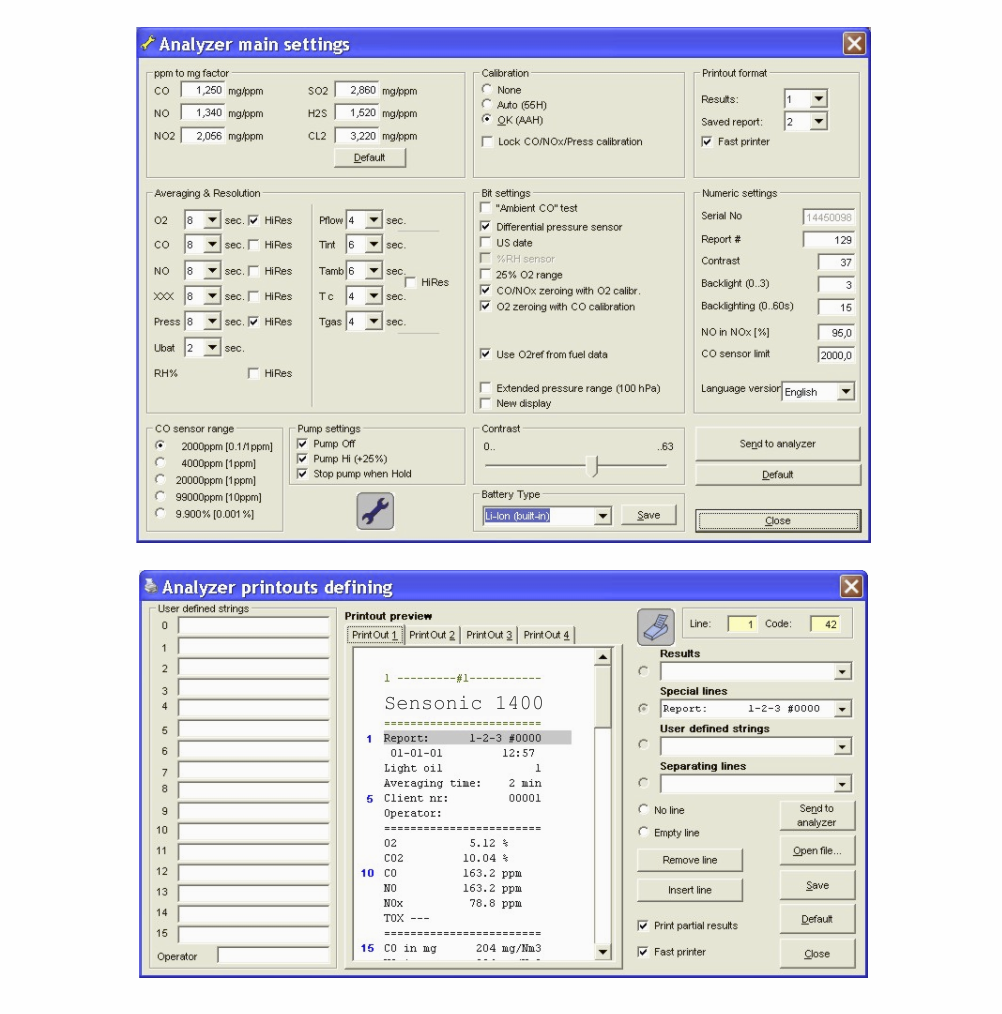

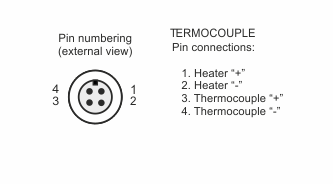

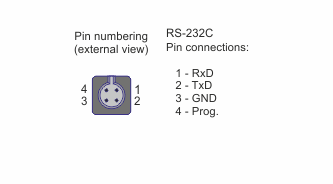

| Communication interface with PC computer | RS-232C |

| Gas filtering | In-line filter included in the gas probe hose |

General parameters - Version B (with additional second pressure sensor)

| Dimensions (W x H x D) | 243 x 130 x 60mm 271 x 130 x 60mm (with gas connectors) |

| Weight | 635g |

| Housing material | ABS case, rubber protective boot (optional) |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Power supply | Built-in Li-ion rechargeable battery (1600mAh) |

| Operating time | Up to 16 hours |

| Number of gas sensors | 3 or 4 |

| Memory for results | For 64 measurement reports |

| Display | Graphical LCD 128x64, with variable contrast and LED backlight |

| Gas pump | Diaphragm, max 0.6 ÷ 0.9l/min. |

| Printer | External thermal IR printer MCP 8850 with charger |

| Communication interface with PC computer | RS-232C |

| Gas filtering | In-line filter included in the gas probe hose |

Measurements of gas components

The analyser can be equipped with sensors from below list

| O2-A2 – (EC) | 20.95%, 25% |

| CO-AF – (EC) | 2000ppm, 4000ppm, 20 000ppm |

| CO-AE – (EC) | 10% |

| CO-AX – (EC) | 4000ppm |

| NO-AE – (EC) | 2000ppm |

| NO2-AE – (EC) | 1000ppm |

| SO2-AE – (EC) | 2000ppm |

| H2S-AE – (EC) | 2000ppm |

EC - Electrochemical sensor

Other measurements / calculated results

| Method | Range | |

|---|---|---|

| Tgas – gas temperature | K-type or S-type thermocouple | -10 ÷ 1000°C | 0.1°C |

| Tamb – boiler intake air temperature | PT500 resistive sensor | -10 ÷ 100°C | 0.1°C |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa ÷ +25hPa | 1Pa (0.01hPa) |

| Gas flow velocity (optional) | Indirect, with Pitot tube & second pressure sensor | 1 ÷ 50m/s | 0.1m/s |

| RH – relative humidity | SHT11 capacitive polymer sensor (special probe needed) | 5 ÷ 95% | 1% |

| Lambda λ – excess air number | calculated | 1 ÷ 10 | 0.01 |

| qA – stack loss | calculated | 0 ÷ 100% | 0.1% |

| Eta η – combustion efficiency | calculated | 0 ÷ 120% | 0.1% |

Drawings

Drawing #1

Drawing #2

5-pin female socket 719 series

Drawing #3

4-pin female socket 712 series

Drawing #4

4-pin female socket 719 series

Drawing #5

Analyzer’s carrying case

Equipment

Analyser's standard equipment supplied along with the device

- Carrying case for analyser and accessories

- Power supply (charger) for the built-in Li-ion battery with selected type of mains plug

- Comparison scale with paper filters for the soot test

- 2.5m RS-232C communication cable with DB9 female connector

- Software CD with PC software and manuals

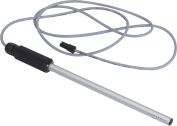

Supplemental Equipment - ordered separately, but essential to work with the analysers

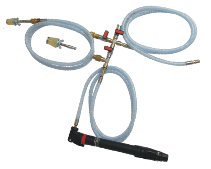

Probe holder

Gas probe pipe

Optional equipment

Portable printer and printer paper

RH and ambient temperature probe

Ambient temperature sensor

Anchor cone for PT500 ambient temperature sensor

Magnetic holder for PT500 sensor

Pitot tube

RS-232C to USB converter

Bluetooth communication module

Leatherette casing

Rubber protector

Pressure test kit

Li-ion rechargeable battery

In-line filter

In-line filter insert