Primary conditions set to the stationary gas measurement systems are trouble-free operation and long maintenance intervals.

As the analysers very often work in harsh environments: toxic, caustic and much polluted, the proper conditioning of the gas sample is the top priority requirement.

For such applications madur's heated gas filter is an answer that provides proper preparation of the sample and protects fragile and sophisticated components of the gas analyser.

Heated filter was designed as a part of entire sampling system, to work with madur's stationary gas probe and heated hose.

But, thanks to universal couplings and independent power supply filter can work stand-alone with equal success.

Features

- Water present in fumes + gaseous components react and create acids, very often caustic ones. To prevent water condensation and in consequence hindering creation of acids, the gas temperature must be kept above its dew point. Thanks to filter's heating this condition is met. Keeping the gas temperature above its dew point not only prevents creation of harmful acids, but most importantly, enables undisturbed measurement of gases that easily reacts with water.

- Filter's casing allows easy access to its insert (that is washable, made of sintered stainless steel). Simultaneously with accessing the insert, maintenance crew has possibility to remove dust / soot residues that deposit inside it.

- Cooperation with madur sampling system elements (heated hose, stationary probe pipe)

- Cooperation with external systems - thanks to filter's universal connection ends - stainless steel pipe, OD=10mm - that can be clamped with e.g. Swagelok or DK-Lok couplers

Tech specs

General Parematers

| Dimensions (H x W x D) | 193mm x 122mm 122mm |

| Weight | 2kg ÷ 3kg |

| Casing's material | Aluminium, anodic oxidized |

| Gas path material | Stainless steel (fittings, filter compartment), silicone rubber (sealings) |

| Storing temperature | -20°C ÷ 60°C |

| Operating conditions | T: -20°C ÷ 40°C, RH: 5% ÷ 90% (non-condensing) |

| Power supply: input | maximal power consumption | 115V AC or 230V AC | 100W |

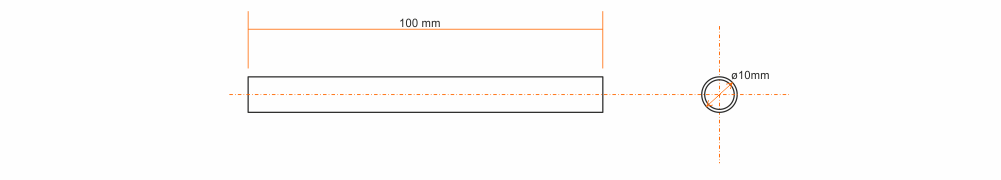

| Filter: material | OD | ID | length | pore size | Siperm R (sintered stainless steel) | 30mm | 26mm | 90mm | 25µm |

| Gaseous connections: type | material | DK-Lok DFS-10M | stainless steel |

| Warming-up time | 10min |

| Desired filter temperature | ~130°C |

Drawing

Drawing #1

Heated filter - external dimensions

Drawing #2

Heated filter - external dimensions

Drawing #3

Heated filter - external dimensions

Drawing #4

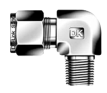

Union elbow 10mmx10mm (stainless steel) - 616G1010A

Drawing #5

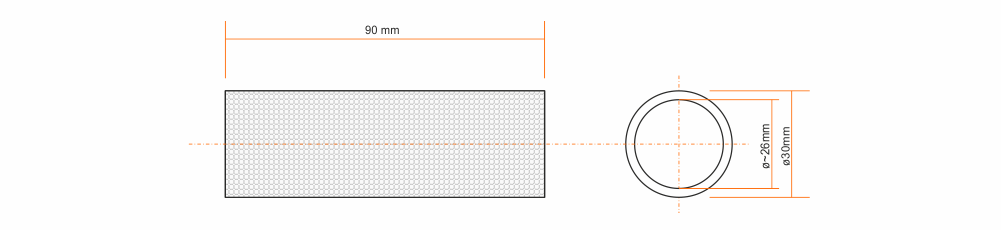

Male elbow 10mm | 1/4 NPT outisde thread (stainless steel) - 616G1010B

Drawing #6

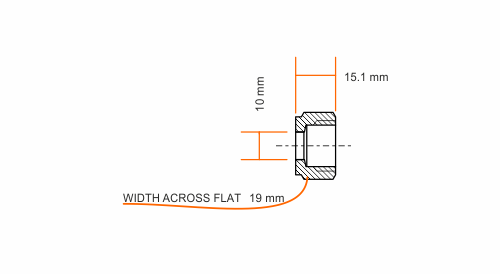

Tightening nut for 10mm pipe (stainless steel) - 616G0010A

Drawing #7

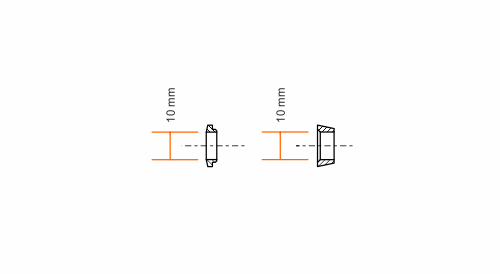

Tightening rings for 10mm pipe (stainless steel) - 616G0010B

Equipment

Heated filter standard equipment supplied along with the device

- Heated filter with 2 gas connections (for smooth 10mm pipe)

- Filter is adjusted to a selected power supply voltage (115V or 230V AC) and is equipped with 5m cable (without the plug)

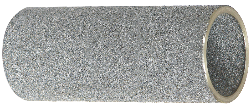

- Additionally, filter is supplied with 2 stainless steel pipes (length=100mm, OD=10mm) to connect the filter to the process installation

- Also, provided with filter insert, made of sintered stainless steel (90mm x 30mm)

Supplemental equipment - ordered separately, but essential to work with the analyser

Filter insert

V-Ring seal

O-Ring 76mm x 4mm

Elbow #1

Elbow #2

Tightening nut 10mm

Tightening rings for the 10mm pipe